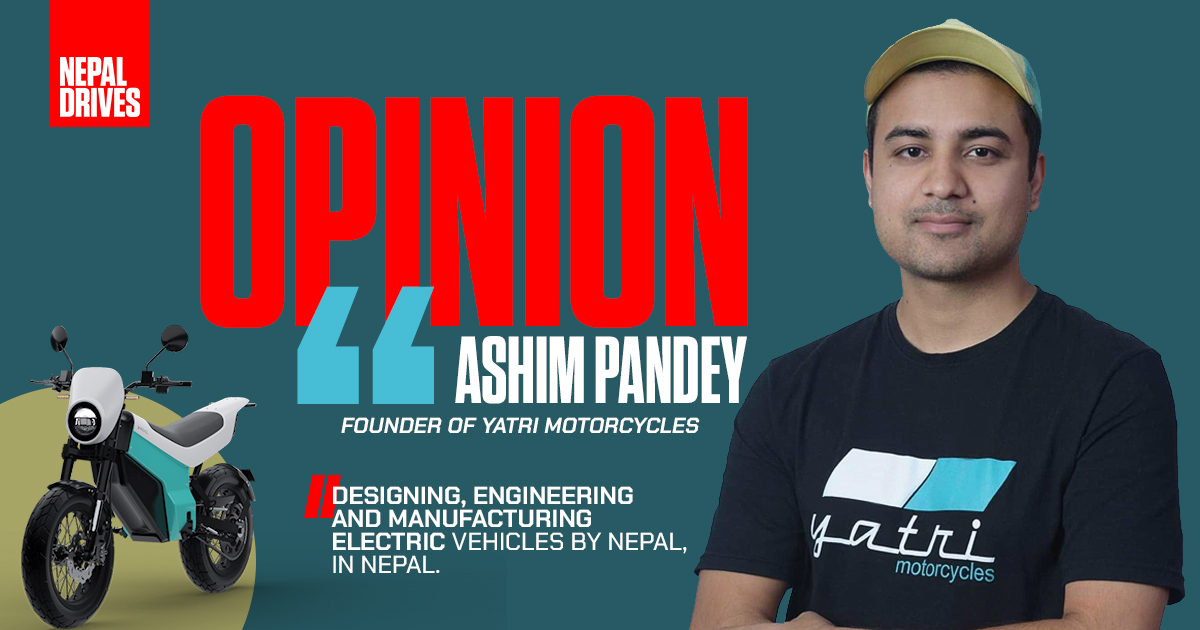

Ashim Pandey, Founder of Yatri Motorcycles, talks about the impact and future of manufacturing electric vehicles in Nepal and the government’s role in the process.

Electrification of the mobility domain is the next shift in paradigm and the world has already begun transitioning to this change. All of the major OEMs have initiated R&D to develop their own electric vehicles in their product portfolio. Furthermore, many nations have also already mandated the use of electric vehicles and plan to completely ban the use of fossil-fueled vehicles by as early as 2030.This transition is, in many ways, very important for Nepal. Our 100% hydro-powered electricity generation means operations of these EVs will be 100% green and sustainable while also increasing the domestic electricity production and massively decreasing the usage of imported fossil fuels. This is directly helping reduce the biggest component of the trade deficit of our country. On top of that, transitioning to clean energy in transportation means conserving our environment as our urban cities have started topping the global charts for most polluted cities.

As the relatively new EV industry continues to grow, it becomes even more important for our nation to capitalize on it and to invest and help grow local initiatives that are working towards the development of indigenously manufactured electric vehicles. This not only helps to reduce the trade deficit and conserve the environment but also builds our nation’s own cutting-edge technology, creates hundreds of thousands of highly skilled jobs and manpower, bridges the gap between academia and industry and subsequently gives rise to hundreds of supply-chain companies creating even more jobs.

A registered local OEM like Yatri that designs and engineers its own vehicle, by definition, will have a diverse supply chain whose parts and raw materials will originate from several vendors, both local and foreign; unlike CKD assembly whose parts arrive from one single foreign manufacturer. The incumbent customs directives make these diversely originated parts and raw materials are categorized into spare parts which bear high taxes compared to the taxes levied upon a fully-finished or CKD product that is imported from outside Nepal. For instance, if a foreign electric scooter, a finished product, is imported into the country, it bears a flat 10% customs duty among other taxes. However, most of the parts and raw materials required by a registered local manufacturer bear custom duty as high as 40%. This already puts the local manufacturer at a big disadvantage and does not provide a level playing field.

The government's policy assistance is critical to continue developing the EV industry and supporting local manufacturing and technology firms while creating hundreds of thousands of highly skilled jobs in the country. Customs tax exemption or reduction for raw materials of registered local manufacturers on items of their vehicle Bill-of-Material (BOM) will be critical. This assistance in establishing local manufacturers and industries will usher in a new age of industrialization, the return of talent to the country, the development of capital goods for export to the rest of the world, and, most importantly, the production of capital goods to export to the world and importantly build our nation for a prosperous future.